Solan Safety Systems

Established in 2005 with the objective of optimizing refrigerated transport, Solan has since been the source of an array of sophisticated solutions, mainly in the field of industry safety in factories and in logistic facilities. Sales of safety products in the logistics sector are constantly on the rise and in 2008 Solan began exporting worldwide.

Improving on imported products, Solan has devised its own proprietary solutions featuring unique, complementary capabilities that optimize safety and performance of forklifts. Our skilled workforce of engineers, technicians and service providers is ready to meet any challenge with tailor-made, integrated solutions.

But not only forklifts. Solan is helping leading companies (such as Teva, Soda Stream and Unilever to name a few) reduce risk and streamline their processes with field-proven products such as: iStop, DFM, Observation Post, Atalef & Buzz tested in the most challenging environments. These and other innovative solutions are saving lives daily, outpacing industry standards and making business more efficient

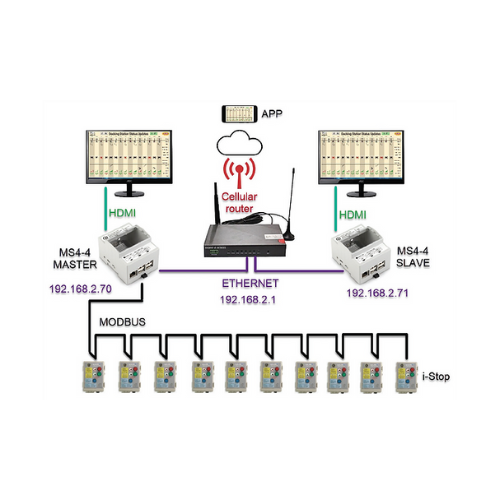

i-Stop Wireless

i-Stop Matrix

SOZ3 System

JOP System

Alerting Observation Post